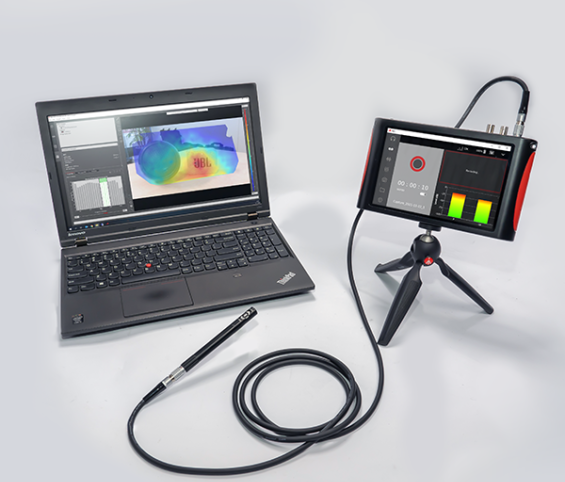

Microflown Scan & Paint 2D

MF002

Product Full Description

Microflown probes enable the direct measurement of both sound pressure & particle velocity, thus the sound intensity can be obtained by taking the time-averaged cross-spectrum between both.

This allows for direct measurements across a broad frequency range (20Hz to 10kHz). Furthermore, the sensors are not highly affected by the environment and allow sound intensity measurements in situations with a high sound pressure over sound intensity ratio (p/I index). This unique feature makes the system a superb engineering tool for troubleshooting or benchmarking all kinds of objects on the spot.

High resolution mapping of: Particle velocity, Sound intensity, Sound pressure, Sound pressure contribution (available with the TPA module), Transmission loss coefficient (available with the TL module), Absorption coefficient (available with In-Situ Absorption add-on)

In practice, there are many cases where anechoic conditions are not applicable, for instance in an industrial manufacturing environment, or a car interior. Finally, a solution is offered which does not require any compromise when taking measurements even in acoustically challenging environments.

The tracking camera, which automatically tracks the position and orientation of the sensor, can be repositioned easily during measurement sessions, providing flexibility together with the ability to capture complex objects, such as a car interior in full 3D. Multiple measurements from different camera views can be merged into one full 3D project.

FEATURES for the Scan&Paint 2D system

Hardware

Scan and Paint Software

Download